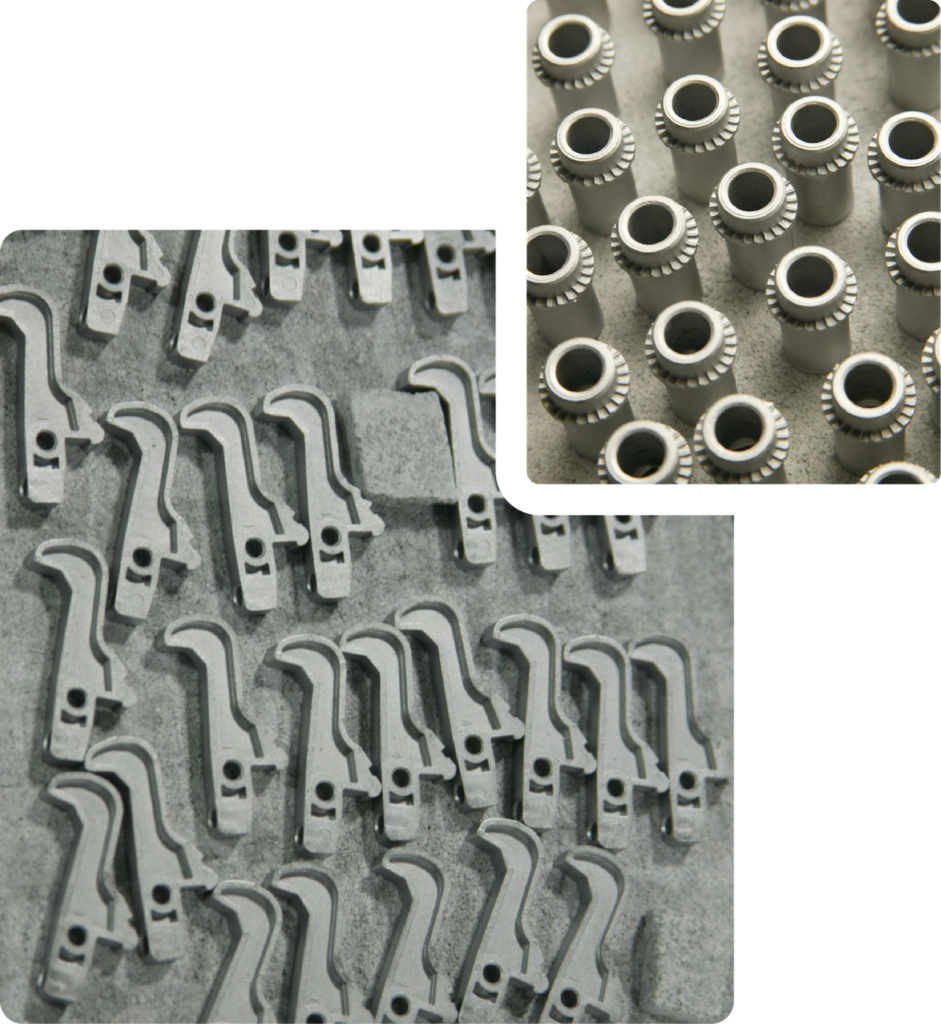

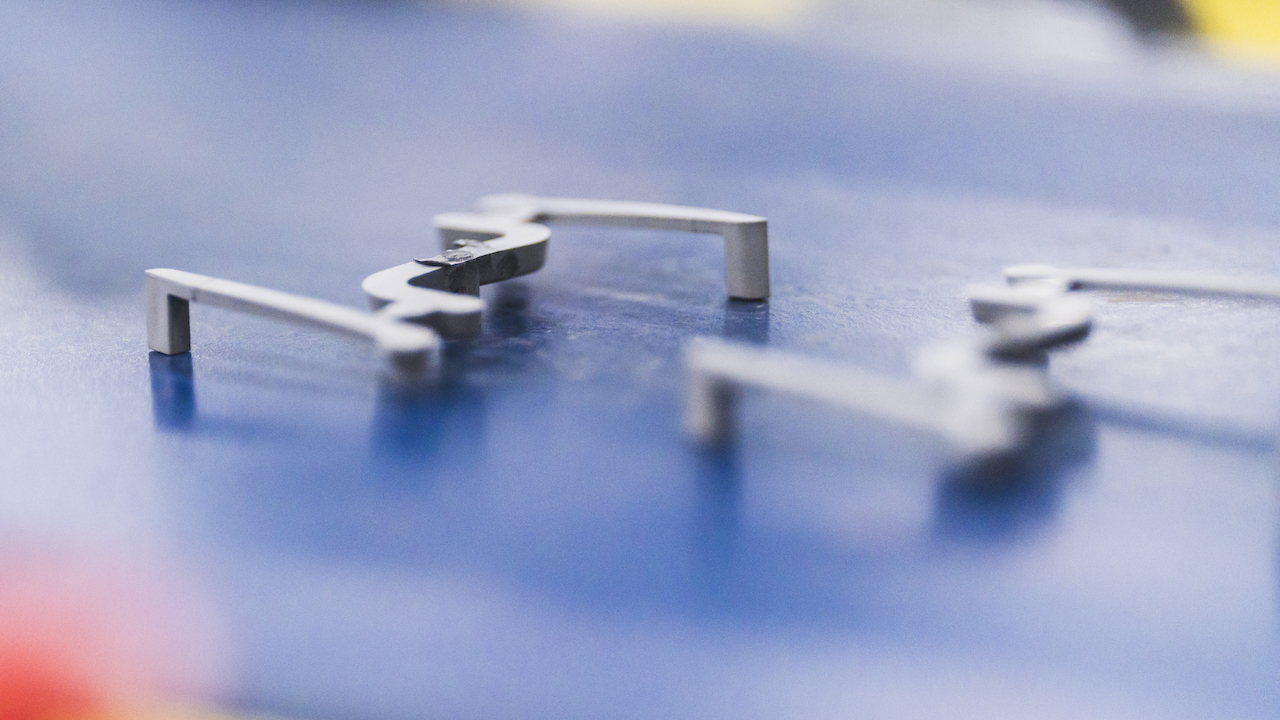

Creative solutions made with MIM

Flexibility with Strength

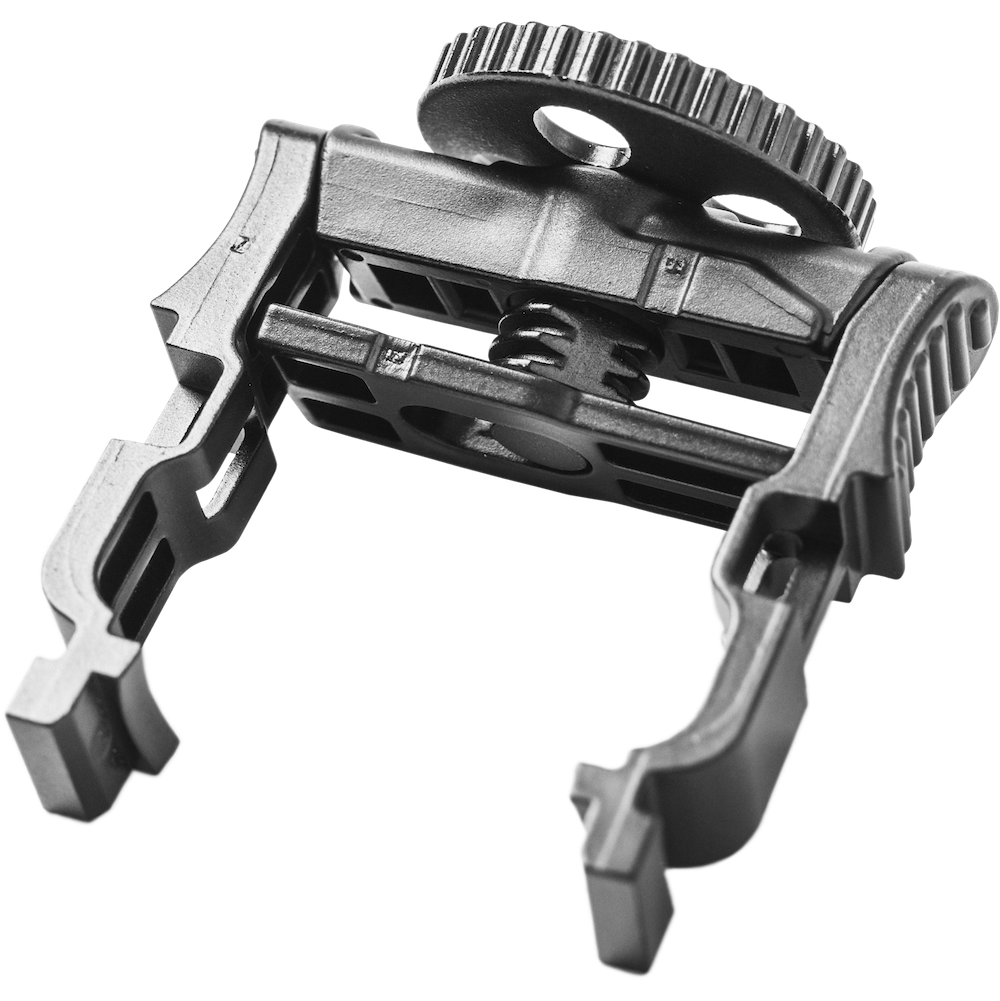

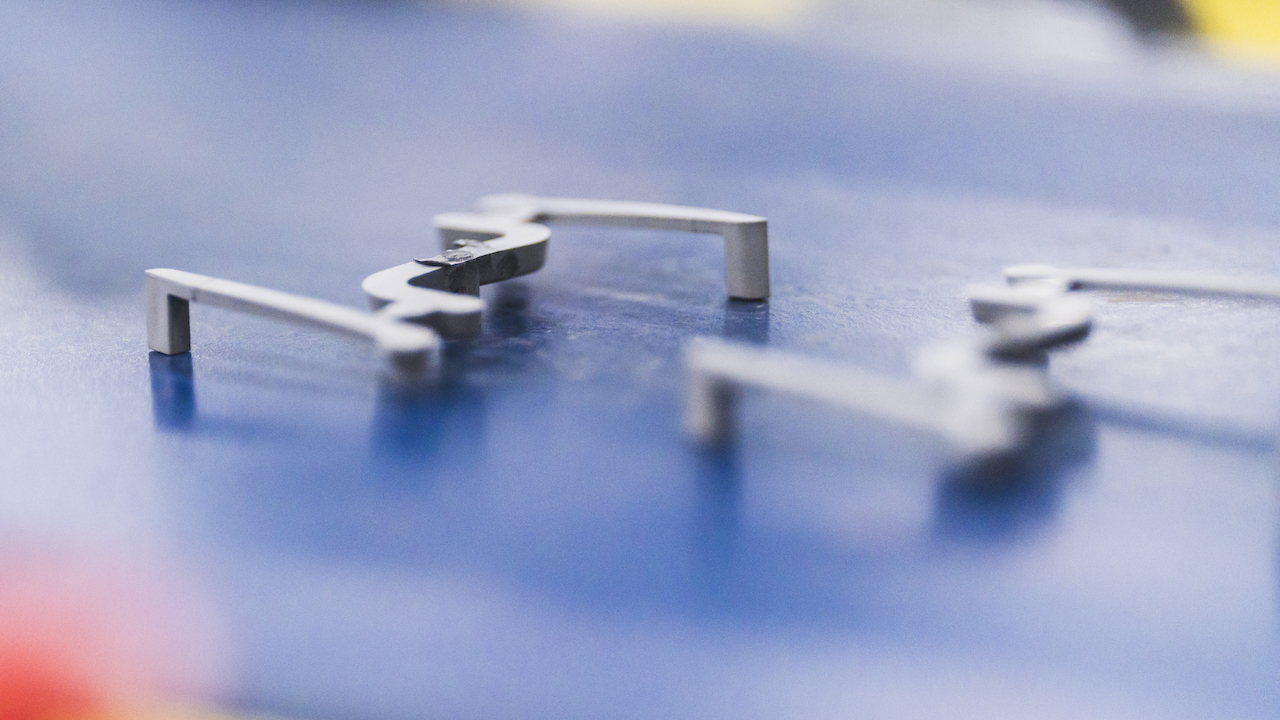

Metal Injection Molding (MIM) combines the design flexibility of plastic injection molding with the strength and durability of metal materials. MIM is a cost-effective alternative to traditional metal manufacturing processes, making it a popular choice in industries such as aerospace, automotive, and medical devices.

Advantages of MIM

- Complex geometries

- Efficient use of material

- Less material waste as a result of producing near net shape components and considered a green technology

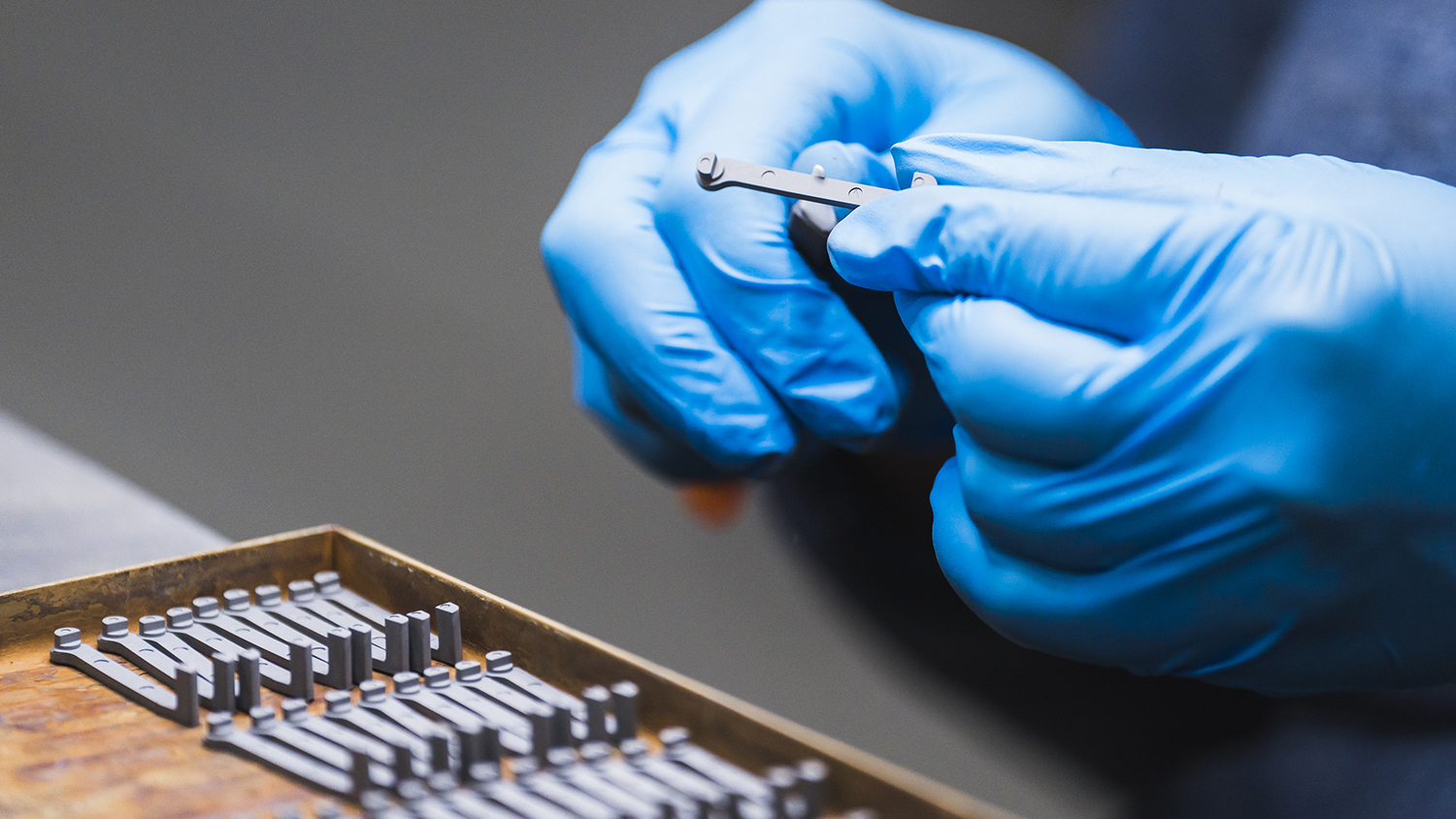

- Repeatability

- Excellent mechanical properties

- Tailored solutions using unique materials formulated to meet component/application requirements

- Can be brazed/joined to a variety of components for complete assembly solutions

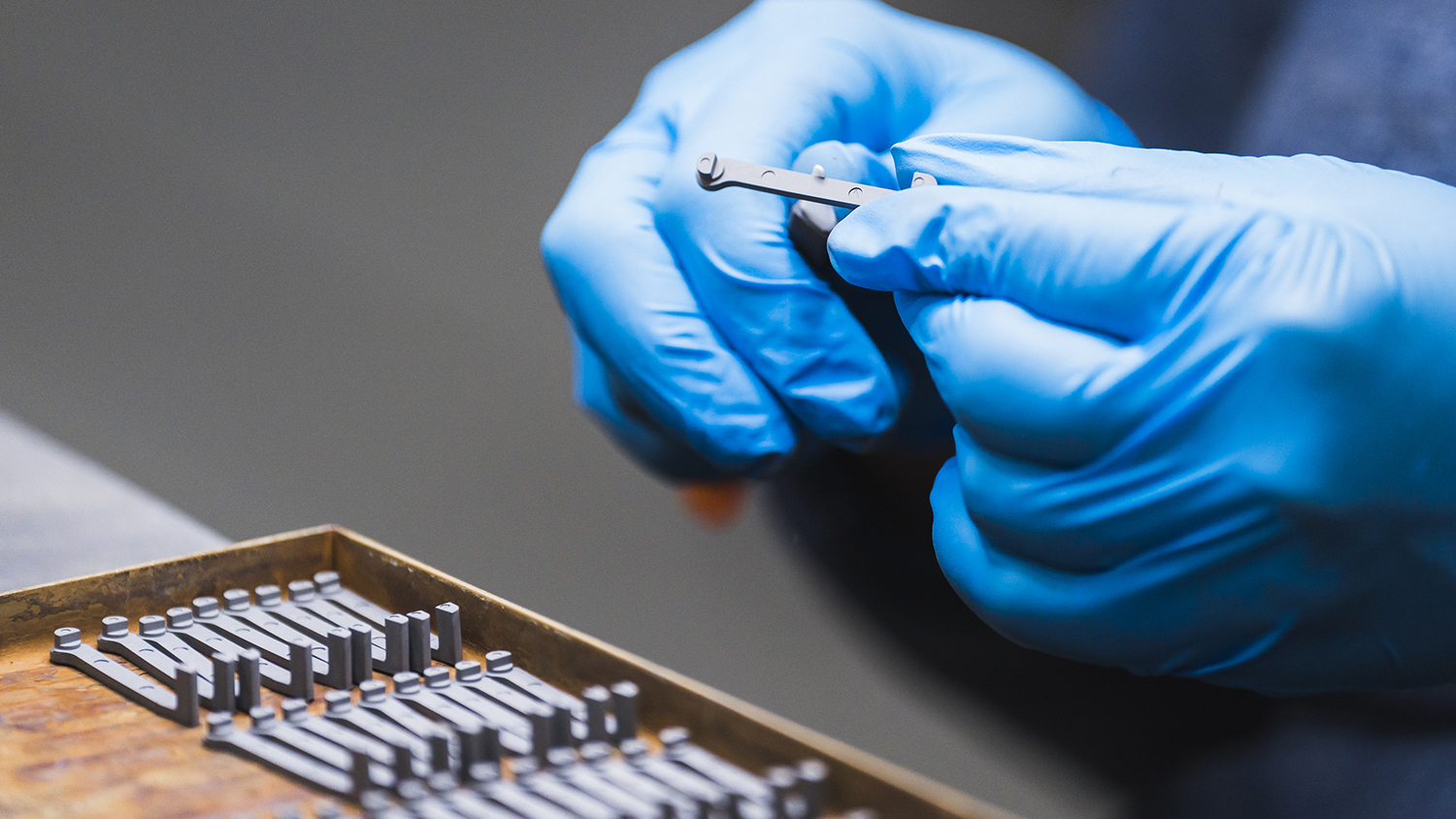

MIM Process

Compounding

Injection

Debinding

Sintering

Secondary

Compounding

Injection

Debinding

Sintering

Secondary

Questions about our process?

MIM components excel in a variety of applications and markets.

Learn about our solutions across multiple industries.

MIM Materials

The MIM process uses a wide array of alloys and metals. From stainless steel to tungsten alloy to low alloy steel, and more, MPP provides expertise in working with any material used in the MIM process. MIM is an excellent alternative to other forming processes, including Inconel casting for aerospace manufacturing.

The most commonly used elements in MIM processing are:

- Iron

- Nickel

- Chromium

- Molybdenum

Iron and nickel are two of the easiest elements to process because of their compatible melt temperature and ease of sintering. Iron and nickel make up a significant amount of the total tonnage produced in the industry.

MPP’S MOST POPULAR MIM MATERIALS

Superalloys

- A-286 – Excellent corrosion resistance, high temperature strength

- Hastelloy X – Good oxidation resistance, high temperature strength

- Inconel 625 – Excellent corrosion and heat-resisting characteristics

Stainless Steels

- 17-4PH – Best combination of strength and corrosion resistance

- 316 – Excellent corrosion resistance

- 420 – High hardness

Low Alloy Steels

- 2200 – Similar to PM FN-0200, good magnetic and toughness properties

- 4605 – High treatable, high-strength steel, up to HRC 52

- 4140 – Heat treatable, high-strength steel, up to HRC 60

Controlled Expansion Alloys

- Fe-Ni – The alloy composition (ie, Invar, Alloy 42, etc) can be tailored for the application’s thermal expansion requirement

- F15 – AKA Kovar®, the alloy is engineered for hermetic glass-metal seals

High Density Alloys

- W-based – High temperature sintering proficiency allows various tungsten-nickel-iron alloy capability; sintered densities range up to 18 g/cc

Soft Magnetic Alloys

- Fe-Si – Silicon content up to 9% allows for high resistivity with good soft magnetic response

- Fe-Co – Excellent magnet saturation properties